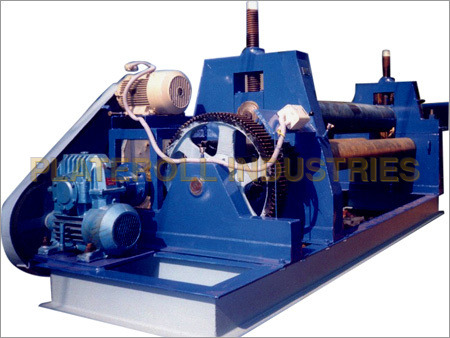

3 Roll Plate Bending Machine (Length- 3000mm; Capacity- Up To 40 mm)

MOQ : 1 Number

3 Roll Plate Bending Machine (Length- 3000mm; Capacity- Up To 40 mm) Specification

- Bend Radius

- 600 Millimeter (mm)

- Place of Origin

- India

- Output

- Rolled/Bent Plates

- Weight

- 15000 Kilograms (kg)

- Dimension (L*W*H)

- 5400 mm x 2100 mm x 2100 mm Millimeter (mm)

- Color

- Standard Industrial Grey & Blue (customizable)

- Raw Material

- Steel Plates, Alloy Plates, Stainless Steel

- Production Capacity

- 5 - 7 Ton/day

- Phase

- 3 Phase

- Bending Strength

- Up to 1,200 MPa

- Bending Speed

- 3 - 6 m/min (variable)

- Machine Type

- Hydraulic, Mechanical

- Bending Angle

- Up to 360 degrees (full cylinder forming possible)

- Voltage

- 380/415/440 Volt (v)

- Automation

- Semi-Automatic / Fully Automatic (as per requirement)

- Condition

- NEW

- Usage

- Plate bending, rolling, forming for fabrication, construction, shipbuilding, and industrial use

- Motor Speed

- 1440 RPM

- Main Drive Motor

- 50 - 75 HP (Varies with model)

- Transmission Type

- Gear Driven/Chain Driven

- Roll Adjustment

- Hydraulic/Electric Adjustment

- Control Panel

- PLC Based with Touch Screen (optional)

- Roll Material

- Forged Alloy Steel

- Safety Features

- Emergency Stop, Safety Guarding, Overload Protection

- Display System

- Digital Position Indicator

- Roll Diameter

- 500 mm - 600 mm (as per specification)

- Surface Finish of Rolls

- Polished for reduced plate marking

- Lubrication System

- Automatic Centralized Lubrication

- Pre-Bending Capability

- Available for edge forming

3 Roll Plate Bending Machine (Length- 3000mm; Capacity- Up To 40 mm) Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

About 3 Roll Plate Bending Machine (Length- 3000mm; Capacity- Up To 40 mm)

Experience pivotal performance with our 3 Roll Plate Bending Machine, engineered for optimum results and immaculate finish. Crafted with forged alloy steel rolls and polished surfaces for reduced plate marking, this robust solution bends plates up to 40 mm thick and 3000 mm in length. With gear/chain driven transmission, hydraulic/electric roll adjustment, and advanced safety features, every process is securely controlled. Limited stock available for a reduced price, for a limited time only. Secure this reliable component, ideal for fabrication, construction, and industrial projects demanding superior bending strength.

Distinctive Features and Versatile Applications

The 3 Roll Plate Bending Machine boasts exceptional features including an automatic centralized lubrication system, PLC-based control panel with optional touch screen, and a digital position indicator. Designed for mechanical or hydraulic operation, it ensures precise plate rolling and forming for fabrication, construction, shipbuilding, and general industrial use. Its advanced safety features, optimum bending speed, and polished rolls deliver immaculate results across steel, alloy, and stainless steel materials, setting a benchmark in performance and reliability for manufacturers.

FOB Port & Market ProposalOffers Delivered Nationwide

Our limited time proposal amount is exclusive for direct offers through Indias main domestic market. The machine is delivered via major FOB ports, ensuring timely and secure shipment to the required destination. Sample availability allows for comprehensive evaluation before finalizing purchase. Benefit from prompt support and customized solutions delivered nationwide by trusted suppliers, exporters, and distributors, matching your fabrication and plate bending needs with precision and efficiency.

Distinctive Features and Versatile Applications

The 3 Roll Plate Bending Machine boasts exceptional features including an automatic centralized lubrication system, PLC-based control panel with optional touch screen, and a digital position indicator. Designed for mechanical or hydraulic operation, it ensures precise plate rolling and forming for fabrication, construction, shipbuilding, and general industrial use. Its advanced safety features, optimum bending speed, and polished rolls deliver immaculate results across steel, alloy, and stainless steel materials, setting a benchmark in performance and reliability for manufacturers.

FOB Port & Market ProposalOffers Delivered Nationwide

Our limited time proposal amount is exclusive for direct offers through Indias main domestic market. The machine is delivered via major FOB ports, ensuring timely and secure shipment to the required destination. Sample availability allows for comprehensive evaluation before finalizing purchase. Benefit from prompt support and customized solutions delivered nationwide by trusted suppliers, exporters, and distributors, matching your fabrication and plate bending needs with precision and efficiency.

FAQs of 3 Roll Plate Bending Machine (Length- 3000mm; Capacity- Up To 40 mm):

Q: How does the 3 Roll Plate Bending Machine ensure operator safety during use?

A: The machine features advanced safety measures such as emergency stop buttons, robust safety guarding, and overload protection integrated within the control panel. These pivotal safeguards guarantee operator protection and compliance during every operational process.Q: What is the process for adjusting roll positions on this plate bending machine?

A: Roll adjustment is achieved through either hydraulic or electric mechanisms, providing precise and smooth movement. The digital position indicator allows operators to monitor and set immaculate roll positions for optimum plate bending outcomes.Q: When can I expect delivery after placing an order for the machine?

A: Delivery timelines depend on the proposal amount and offer acceptance. Machines are shipped via major FOB ports throughout India, with prompt delivery schedules managed by our nationwide distributor network to minimize waiting periods.Q: Where can samples be viewed before purchasing the 3 Roll Plate Bending Machine?

A: Samples and demonstrations are available through authorized suppliers, distributors, and showrooms across Indias main domestic markets. You can arrange a viewing and proposal to evaluate machine performance prior to purchase.Q: What are the benefits of the machines automatic centralized lubrication system?

A: The automatic centralized lubrication system maintains optimal performance by reducing friction and wear on rotating components. This ensures longer machine life, reduced maintenance intervals, and consistent delivery of high-quality bent plates.Q: How is the bending speed and angle controlled during operation?

A: Bending speed (36 m/min) and bending angle (up to 360) are variable and managed through the PLC-based control panel, providing flexibility according to material thickness and fabrication requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plate Bending Machine Category

Industrial Plate Bending Machine

Minimum Order Quantity : 1 Piece

Product Type : Sheet Bending Machine

Automation : Yes

Motor Speed : 1440 RPM

Power : 12 kW (Approx.)

3 Roll Plate Bending Machine (Length- 3000mm; Capacity- Up To 20 mm)

Minimum Order Quantity : 1 Number

Product Type : 3 Roll Plate Bending Machine

Automation : SemiAutomatic

Motor Speed : 1440 rpm

Power : 22 kW

Metal Bending Machine

Minimum Order Quantity : 1 Piece

Product Type : Sheet Bending Machine

Automation : Yes

Heavy Duty Plate Bending Machine

Minimum Order Quantity : 1 Piece

Product Type : Sheet Bending Machine

Automation : Yes

|

PLATEROLL INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry